CONCRETE POURING PROCESS FOR COLUMNS, BEAMS AND FLOORS

One of those problems is related to the process of pouring concrete columns, beams, and floors. Understanding the wishes of many investors, this article was written to help you properly, fully, and manage the entire process of pouring concrete columns, beams, and floors while building a house for your family. Below are the notes that investors should follow before, during, and after pouring concrete columns, beams, and floors.

1. Check formwork and steel before pouring concrete

- Formwork must ensure technical requirements: Measure and determine the position of the formwork, the formwork must be firm, tight and prevent water loss when pouring and compacting concrete.

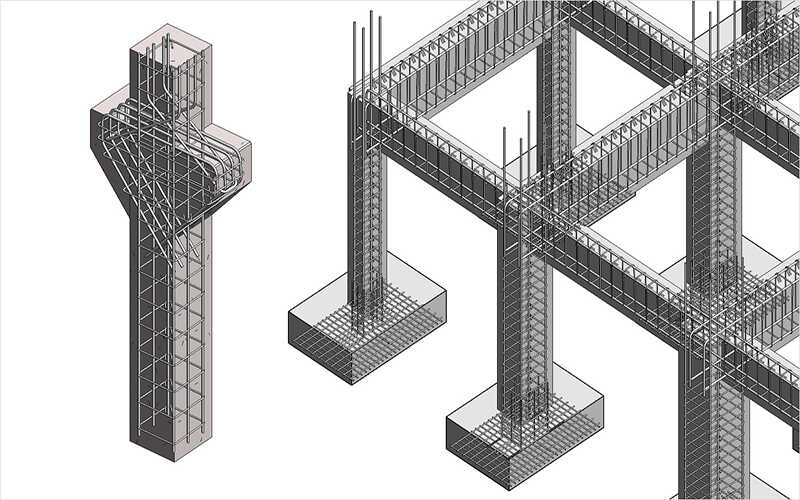

- Column formwork: the formwork legs must be in the correct position, firm to ensure that when pouring concrete, it will not be displaced; column formwork must be supported, anchored, and plumbed to ensure that the column does not tilt or bulge.

- Beam formwork: formwork walls must be straight and not warped, check the height of the beam bottom.

- Floor formwork: check deflection and floor bottom elevation at multiple locations.

- During the process of pouring reinforced concrete, the following criteria must be met: steel type, location, quantity, length, connection, and steel tying must follow the design; cleaning and rusting the steel.

2. Preparation process before pouring concrete.

To have a beautiful villa design, the investor needs to have a careful preparation process, including design and construction. In the preparation process before pouring concrete, the investor needs to prepare to perform the following steps:

- Prepare, calculate human resources, machinery and equipment to ensure the concrete pouring process.

- Calculate the concrete pouring time.

- Calculate the concrete pouring construction site.

- Ensure safety during construction during the process of pouring concrete columns, beams, and floors.

- Clean and flush the formwork and steel reinforcement.

3. Detailed instructions on the process of pouring concrete for columns, beams, and floors

3.1 Column concrete pouring process

- Put concrete into the pouring block through the pouring door through the pouring chute.

- The free fall height of the concrete is not more than 2m.

- The rammer is put in to compact vertically, using a rammer to compact, the depth of each layer of concrete when ramming is about 30 - 50cm, the compacting time is about 20 - 40s. Pay attention during the compacting process to avoid misaligning the steel.

- Note that for structures with doors, when pouring to the pouring door, close the door and continue pouring the upper part.

- When pouring concrete, the lower layer of the column is often pitted because large aggregates often accumulate at the bottom. To overcome this phenomenon, before pouring concrete, pour a layer of cement mortar about 10 - 20cm thick.

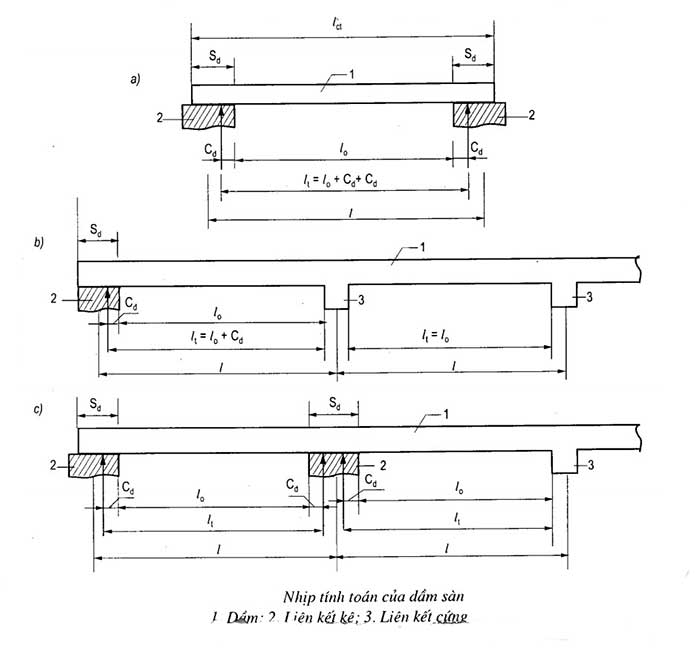

3.2 Beam concrete pouring process

-

In residential houses, the height of the beam rarely exceeds 50cm, so people often pour concrete beams together with the floor slab. In special cases where the height of the beam is greater than 80cm, concrete beams are poured separately from the floor slab. With this type of beam, concrete is not poured in layers along the entire length of the beam, but is poured in a step-like manner, each section is about 1m long, reaching the height of the beam before pouring the next section.

-

When pouring concrete for the entire beam and floor slab connected to the column, it is important to note that after pouring the column to a height of 3-5cm from the bottom of the beam, we must stop for 1-2 hours to allow the concrete enough time to shrink before pouring the beam and floor slab. Normally, when done manually by a small number of workers, this work is divided into two stages, the first stage is when the column is poured, then the beam and floor slab formwork is assembled to continue with the second stage.

3.3 Concrete floor pouring process

- The floor is also similar in structure to the beam, but the floor has a wider cross-section and a smaller thickness, so there is no need for frame and belt reinforcement. The thickness of a normal residential floor is from 8 to 10cm. Floor concrete usually does not require high waterproofing and heat resistance like the roof, but it must also comply with maintenance to avoid cracking. The floor concrete must be poured in a backward direction and in a single layer to avoid possible frequency separation.

- The floor surface is divided into strips for pouring concrete, each strip is 1 to 2m wide. After pouring a strip, pour the next strip. When pouring to about 1m from the main beam, start pouring the main beam. Pour concrete into the beam to about 5 to 10cm from the top of the floor formwork, then continue pouring the floor concrete. When pouring floor concrete, it is necessary to control the height with the gauges, otherwise the concrete will be wasted at this stage. Use a wooden trowel to beat and smooth the surface after thoroughly tamping.

- The concrete block to be poured must always be at a lower position than the position of the concrete transport vehicles, that is, the concrete transport route must be higher than the structure. Pouring concrete on the floor starts from the farthest point from the receiving position and gradually moves back to the nearest position. Avoid allowing water to accumulate at the two ends and corners of the formwork, along the formwork compartment walls. All operations such as compacting, leveling, and smoothing must be carried out immediately in a "rolling" manner for each area that has been poured for 15 minutes.

3.4. Some practical notes when pouring concrete columns, beams, floors

- Construction safety: When pouring concrete, pay close attention.

- Note when to remix concrete: Concrete mortar that has been mixed for about 1 hour and 30 minutes but has not been poured into the mold needs to be remixed. However, do not add water. Because water-shrinking concrete mortar is less flexible to operate, but the quality is not reduced. If water is added, the excess water will make the concrete mortar soft, reducing its bearing capacity.

INTRODUCING A REPUTABLE DESIGN & CONSTRUCTION CONSULTING SERVICE PROVIDER

The importance of construction units is undeniable, their reputation will ensure the quality and aesthetics of your project. Currently, there are many units providing design and construction services to meet the increasing construction needs in our country. Therefore, finding a reputable unit is not easy and requires you to spend time researching. In the selection process, you need to research carefully and ensure that the accompanying unit must have high expertise, many years of experience, have a clearly signed contract, transparent costs, ... To help customers save time searching, Hung Nghiep Phu Construction Investment Co., Ltd. is confident that it will be the best choice for you.

Hung Nghiep Phu Construction Investment Co., Ltd. with the mission of providing the best solutions and services, building a prosperous community with customers, Hung Nghiep Phu is gradually affirming its brand through sincere cooperation, with a leadership team with ethical capacity, creativity, high expertise and strategic vision. Hung Nghiep Phu owns a team of skilled, highly qualified employees who will bring customers the best quality technology.

Hung Nghiep Phu Construction Investment Co., Ltd. - specializes in constructing civil and industrial works. We look forward to accompanying customers in construction projects as well as continuous procedures such as planning diagrams, applying for construction permits, completing procedures, applying for fire prevention and fighting certificates, ... If you have any questions or are in need of design, completing procedures, please contact us immediately for free consultation!

>>> See more:

_____________________

CONTACT INFO:

![]() Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

![]() hotline: 1800.3368 (Miễn phí)

hotline: 1800.3368 (Miễn phí)

![]() Website: xaydunghungnghiepphu.com

Website: xaydunghungnghiepphu.com

![]() Gmail: kinhdoanh01@xaydunghungnghiepphu.com

Gmail: kinhdoanh01@xaydunghungnghiepphu.com

![]() Address: No. 2034D, Group 22, Phuoc Thai Hamlet, Tan Khanh Ward, Ho Chi Minh City

Address: No. 2034D, Group 22, Phuoc Thai Hamlet, Tan Khanh Ward, Ho Chi Minh City

------

Source: Compiled from the Internet