FIRE PROTECTION REGULATIONS IN FACTORY CONSTRUCTION

Factory construction has many potential risks of fire and explosion, concentrating many flammable materials and dangerous chemicals. This article will provide you with detailed information about fire prevention regulations in construction:

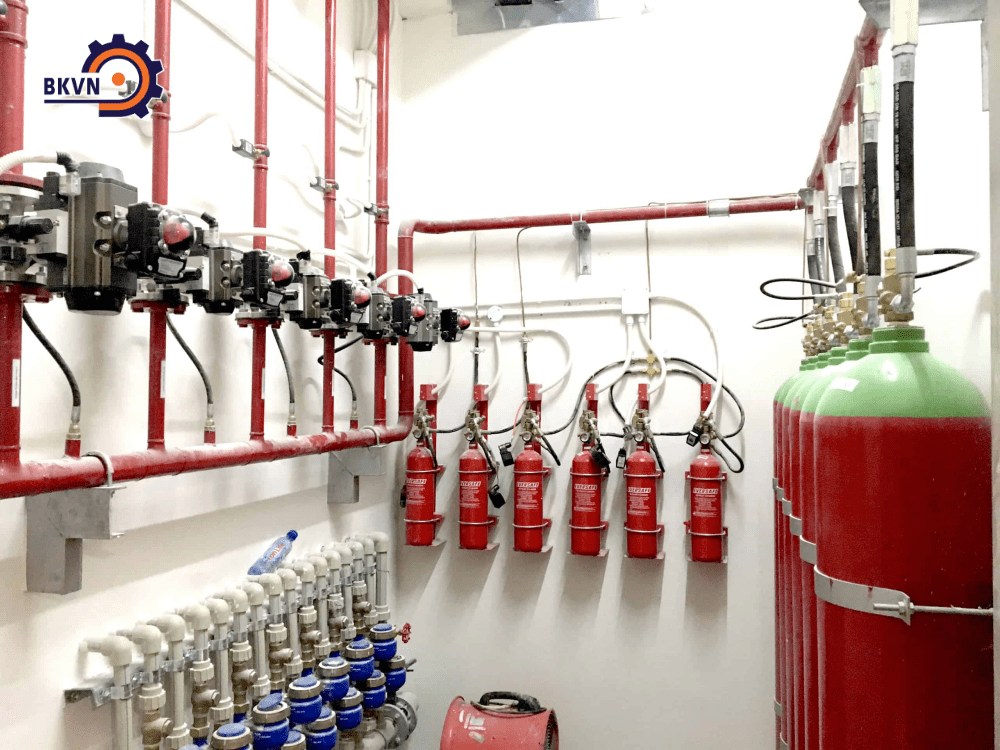

(Illustration)

(Illustration)