NOTES WHEN POURING CONCRETE IN HOT WEATHER

Vietnam is a country with a tropical climate, which directly affects the construction process and the quality of concrete. Especially in the summer, high temperatures greatly affect the process of pouring fresh concrete for architectural works. Therefore, this article would like to share with readers some notes on pouring fresh concrete in hot weather.

In hot climates, the workability of concrete mixtures will decrease; quickly leading to more difficult construction process. Adding water to concrete at the construction site to improve the above situation; although it has been recommended as very dangerous, it is still used. Adding water at the construction site will increase the water/cement ratio, reducing the strength and durability of the concrete.

To ensure that the level of strength reduction of concrete construction materials caused by hot weather is within the allowable limit. The temperature of fresh concrete should be strictly controlled. In some projects in Vietnam, it is required; The initial temperature of fresh concrete should be from 30 - 32oC.

In addition to reducing the strength and durability of concrete; high initial temperature of fresh concrete also leads to some negative effects:

- Causing the hydration process of cement to occur faster, which causes the concrete to harden early - leading to a rapid decrease in the workability of concrete.

- The surface of the concrete dries very quickly, especially under the influence of wind; sunlight and low relative humidity.

To avoid dehydration, the concrete needs to be maintained or continuously sprayed with moisture on the surface. If dehydration occurs, cracks will appear due to plastic shrinkage. In addition, the above process leads to the cement not being able to hydrate completely. Continuing to reduce the final strength of the outer concrete layer that has lost water early. Reducing the durability of the concrete.

Method of controlling the initial temperature of fresh concrete during concrete pouring.

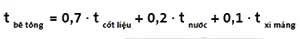

The formula for calculating the initial temperature of fresh concrete (concrete) is established approximately as follows:

Based on the above calculation formula, we can see that controlling the temperature of aggregates; and water is the most effective method to control the initial concrete temperature.

Method to reduce the temperature of fresh concrete

- Cooling aggregates by covering and wetting aggregates.

- Using ice water during mixing/using water chiller.

- Cooling concrete mixture with liquid nitrogen.

Concrete pouring preparation plan

- The concrete supply process must be closely coordinated with the concrete construction process to minimize delays in placing the block.

- Adequate equipment and manpower must be available for the concrete to be placed and compacted quickly.

- The foundation and formwork must be ensured not to absorb water from the concrete. The formwork should be moistened before placing the concrete. However, it is necessary to prevent the formwork and foundation from being sprayed with too much water, causing water to pool.

- If the conditions for construction in hot weather cannot be met, construction should be postponed to a cooler time of the day. For example, construction at night.

- Set retarding admixtures can be used to reduce the disadvantages of rapid cement hydration; but they will prolong the setting time of the concrete slightly. The use of set retarding admixtures also requires the curing time of the concrete to be extended; as they increase the risk of plastic shrinkage cracking. The formwork and the substrate must be ensured not to absorb water from the concrete. The formwork should be moistened before pouring the concrete. However, it is necessary to prevent the formwork and substrate from being sprayed with too much water, causing water stagnation.

- If the conditions for construction in hot weather cannot be met; construction should be postponed to a cooler time of the day. For example, construction at night.

- Set retarding admixtures can be used to reduce the disadvantages of rapid hydration of cement. They will prolong the setting time of concrete slightly. When using set retarding admixtures; it also requires that the curing time of the concrete be extended; because they increase the risk of plastic shrinkage cracking.

When is it permissible to remove formwork

Formwork should only be removed when the concrete structure has achieved sufficient material strength to stabilize the structure. Normally, people often consider the time from 3 to 4 weeks after pouring in normal conditions (20 - 30oC) to be enough to remove the formwork; but if possible, the longer the better. There are many cases where removing the formwork before the specified time has caused the structure to collapse; causing serious accidents. After removing the formwork; it should be noted that the commercial concrete has only reached the strength to withstand static load (ie its own weight); but it will take a long time to withstand the active load (weight of other furniture, equipment. In cases where it is necessary to remove the formwork early; it is necessary to continue to support the structures such as floors, beams and main beams with wooden or metal props.

Introducing a reputable design & construction consulting service provider

The importance of construction units is undeniable, their reputation will ensure the quality and aesthetics of your project. Currently, there are many units providing design and construction services to meet the increasing construction needs in our country. Therefore, finding a reputable unit is not easy and requires you to spend time researching. In the selection process, you need to research carefully and ensure that the accompanying unit must have high expertise, many years of experience, have a clearly signed contract, transparent costs, ... To help customers save time searching, Hung Nghiep Phu Construction Investment Co., Ltd. is confident that it will be the best choice for you.

Hung Nghiep Phu Construction Investment Co., Ltd. with the mission of providing the best solutions and services, building a prosperous community with customers, Hung Nghiep Phu is gradually affirming its brand through sincere cooperation, with a leadership team with ethical capacity, creativity, high expertise and strategic vision. Hung Nghiep Phu owns a team of skilled, highly qualified employees who will bring customers the best quality technology.

Hung Nghiep Phu Construction Investment Co., Ltd. - specializes in constructing civil and industrial works. We look forward to accompanying customers in construction projects as well as continuous procedures such as planning diagrams, applying for construction permits, completing procedures, applying for fire prevention and fighting certificates, ... If you have any questions or are in need of design, completing procedures, please contact us immediately for free consultation!

>>> See more:

_____________________

CONTACT INFO:

![]() Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

![]() Hotline: 1800.3368 (Free)

Hotline: 1800.3368 (Free)

![]() Website: xaydunghunnghiepphu.com

Website: xaydunghunnghiepphu.com

![]() Gmail: kinhdoanh01@xaydunghungnghiepphu.com

Gmail: kinhdoanh01@xaydunghungnghiepphu.com

![]() Address: No. 2034D, Group 22, Phuoc Thai Quarter, Thai Hoa Ward, Tan Uyen City, Binh Duong Province

Address: No. 2034D, Group 22, Phuoc Thai Quarter, Thai Hoa Ward, Tan Uyen City, Binh Duong Province

------

Source: Compiled from the Internet