ROOFING CONSTRUCTION TECHNIQUES

Roofing with corrugated iron is one of the popular construction techniques in the construction industry today. Corrugated iron is not only water-resistant but also lightweight, helping to reduce the load on the structure. Below are detailed instructions on roofing techniques, follow Hung Nghiep Phu to learn more!

1. What is a corrugated iron roof? Structure of corrugated iron roof

1.1. What is a roof?

Metal roofs are increasingly diverse in design to meet the increasing needs of customers with their outstanding advantages.

Metal roofs, also known as roofing sheets, are materials used for constructions to protect the construction from the effects of the external environment such as rain, wind, etc.

Metal roofs can be produced from many different materials, so the prices also vary. The criteria for choosing roofing sheets include: Cost, aesthetics and durability.

Since appearing on the market, the dominant position of tile roofs is no longer the same as before, metal roofs have been popular for a long time and therefore many people have learned, want to be equipped with knowledge about metal roofs and have the need to install metal roofs so that they can carry out the construction themselves. However, metal roofs are not popular for villa models because they do not create luxury but tend to have youthful colors.

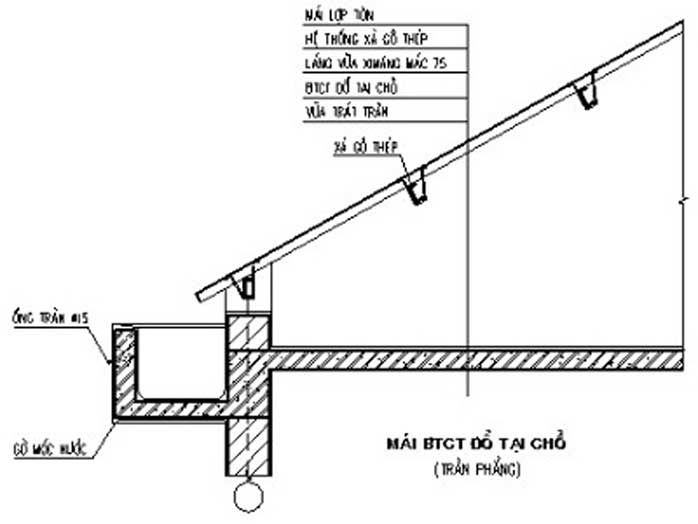

1.2. Structure of the roofing system

Dựa vào đặc điểm cấu tạo của hệ thống mái tôn để biết hướng dẫn thi công lợp mái tôn như thế nào

Frame system: This is the part that bears the heaviest load of the factory, including square iron and iron pipes. The construction has a large area and floor area, so the frame is also large and sturdy, especially now that storms and floods are increasingly severe.

Truss and roofing system: Depending on the area of roofing, the truss and roof beam system will be correspondingly large. And depending on the purpose of use and the nature of the construction, choose heat-resistant roofing with roofing types with many functions.

Screw system: For screws to have high durability, screws should be made of chrome-plated stainless steel, which has both high hardness and good corrosion resistance. The rubber gasket system must be tight to prevent rainwater from seeping in. For the system to withstand storms and storms, when constructing roofing, we also note that we should use additional adhesive.

Especially when completing the frame, we must use a layer of anti-rust paint to prevent the impact of the weather. Because of rust, modern house models often do not use corrugated iron roofs but use Thai tile roofs. But in the city with adjacent constructions, people still use corrugated iron roofs for high-rise buildings.

Upgrading and maintenance: to ensure the durability of the corrugated iron roof system, before completing the project, we should apply a layer of anti-rust or anti-heat paint and professional paints.

Because of its outstanding advantages, it is obvious that many people are interested in corrugated iron roofing construction.

2. Advantages of corrugated iron roofs

Durability

The durability of a metal depends on its composition and microstructural characteristics. Metals used for roofing are usually made of steel, stainless steel, aluminum, copper and alloys of different metals. Therefore, metal roofing can withstand harsh weather conditions.

You can have a wide range of choices in style, design, and color. Metal roofing can make your house look unique because it can significantly change the appearance of a house. The light weight of metal roofing is a big advantage. Metal roofing is much lighter than other roofing materials, especially compared to tiles and concrete roofs, ensuring the foundation structure or not needing to reinforce the house foundation. Besides, it can be easily transported and is suitable for construction works because of its low density. Therefore, the construction of corrugated iron roofing is very simple, without too many complicated details.

Metal roofing panels for roofs can last from 20 to 40 years if the roofing method is properly installed.

Easy to install

Installing metal roofing panels is quicker and easier than other roofing materials, especially in special designs such as large curves or waves. They can be installed on open frames, solid surfaces or on a completed building.

Conventional roofing materials absorb energy from the sun. Metal roofing panels reflect most of the sun's rays, including UV rays from the sun. There are many types of heat-resistant roofing panels available today, helping to keep your home cool. The installation of heat-resistant roofing panels is only slightly different from that of regular roofing panels.

Highly economical

Its lifespan is longer than other materials. In addition, the maintenance cost is almost negligible. Roofing panels are also cheap, so they are widely used. If you want to save money when building a large-scale house, you should use a corrugated iron roof.

However, the composition of the roof is designed to take into account environmental factors and loads. Metal roofing can dent when subjected to strong impact and can cause noise. However, if you use adequate cushioning materials, you can limit these. Although it is durable, dents may still appear occasionally, which can be replaced and repaired very easily. Seal small holes or cracks with cement roofing sheets.

3. Note the remaining limitations

When advising you on how to choose to use corrugated iron roofing products and roofing construction, we also give you some limitations so that you can consider whether to install corrugated iron roofing or not.

- Rust (so you must ensure that the corrugated iron roof is clean to prevent corrosion): corrugated iron roofs are susceptible to rust when exposed to the weather.

- Thermal conductivity: so you must come up with effective heat-resistant methods and now there is an effective way to roof corrugated iron to prevent heat.

- Affecting telephone or radio waves: this was a problem in the past but now it is no longer a concern.

- Not as luxurious as tile roofs, suitable for factory buildings and small-area 1-storey 3-bedroom house designs and simple architecture.

- Because of its light weight, the roof is easily blown off during a big storm.

4. Application of roofing types before roofing construction

The main components of corrugated iron include: color-coated zinc, color-coated aluminum zinc.

Thickness: 0.4mm, up to 0.6mm.

Depending on the function of each project, we recommend that you use corrugated iron appropriately.

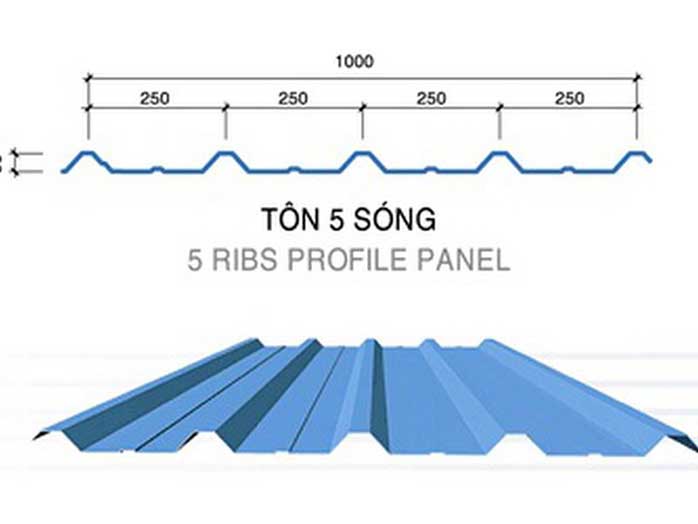

5-wave corrugated iron: Corrugated iron used for roofs, has a fairly large wave height, so it has very good water-proofing ability. The way to cover square corrugated iron is similar to that of regular corrugated iron.

Hướng dẫn thi công lợp mái tôn 5 sóng vuông đơn giản

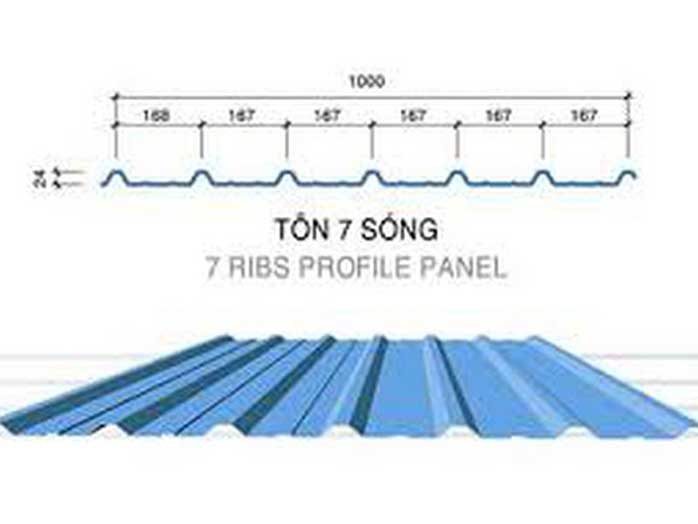

7-wave square corrugated iron: Corrugated iron used for partitions should have a fairly low wave height.

Tôn 7 sóng vuông thường sử dụng làm vách ngăn nên chiều cao sóng tương đối thấp hơn so với tôn 5 sóng vuông

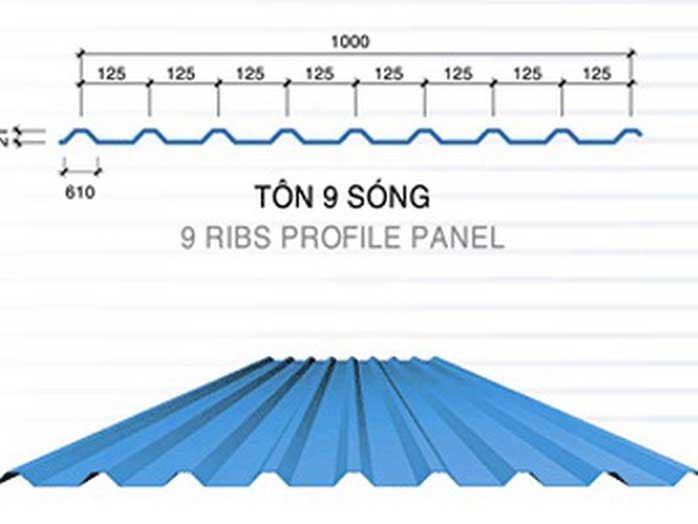

9-wave square corrugated iron: The characteristic of this corrugated iron is that it has low wave height, the largest number of waves is often used for walls, it brings aesthetics to the surface of the construction. When constructing a corrugated iron roof, you need to pay more attention to this type of corrugated iron because it is more complicated.

Biện pháp thi công mái tôn 9 sóng vuông đúng kỹ thuật

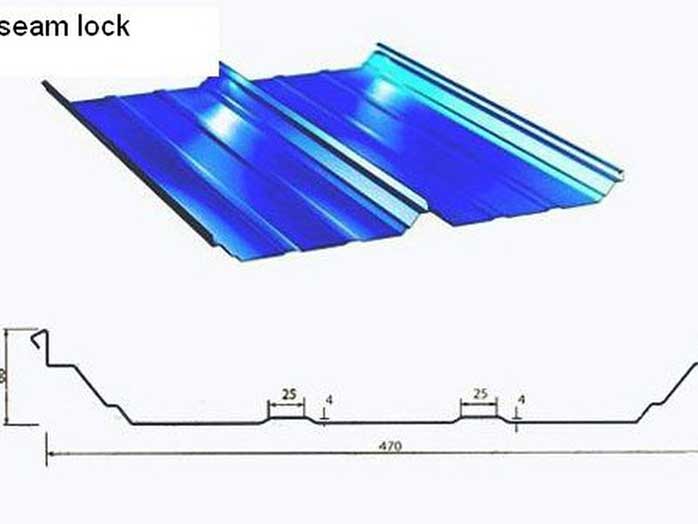

Kliplock corrugated iron: This corrugated iron is used for roofs, does not use screws, has a large wave height and is extremely effective in preventing leaks

Seamlock corrugated iron: This corrugated iron is used for roofs, does not use screws, has a large wave height of up to 84, and is absolutely effective in preventing roof leaks.

Tôn Seam lock là loại tôn mới trên thị trường nhưng cũng được ưa chuộng vì nó chống nước đọng mái rất tốt

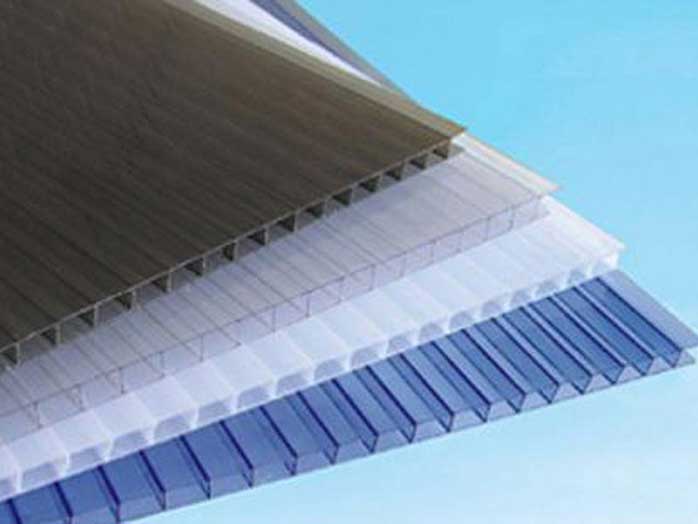

Translucent corrugated iron: This corrugated iron is often used for constructions, it is also used for roofs and walls. The purpose is to get good light, has high transparency, can withstand heat, can withstand pressure and can be seen through.

Tôn lấy sáng là kiểu mái tôn trong suốt có thể nhìn xuyên thấu

5. Roofing construction instructions must be correct.

Constructing a corrugated iron roof with the right technique will ensure the quality of the entire roofing project.

When the corrugated iron roof construction technique is good, repairs due to damage will be significantly reduced.

If the corrugated iron roof is not constructed with the right technique, the aesthetics will be significantly reduced; the durability and lifespan of the project will also be affected; if the corrugated iron roof is made for modern house models; errors must not occur because construction at high altitudes is very dangerous.

The correct and quality construction of the corrugated iron roof will show the reputation of the contractor.

5.1. How to measure

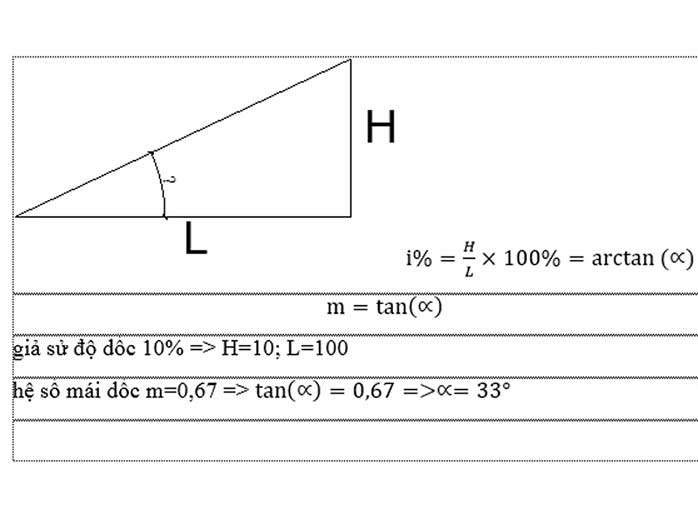

Hướng dẫn cách tính độ dốc mái tôn chính xác

Before you can start installing roofing panels; you will need to take accurate measurements to order materials.

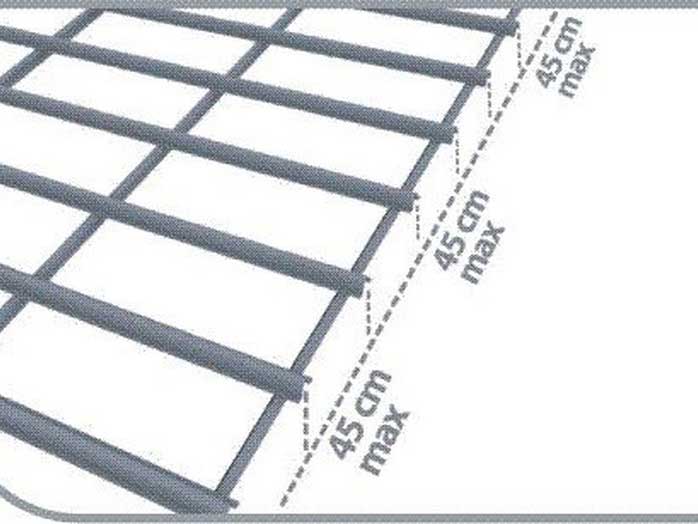

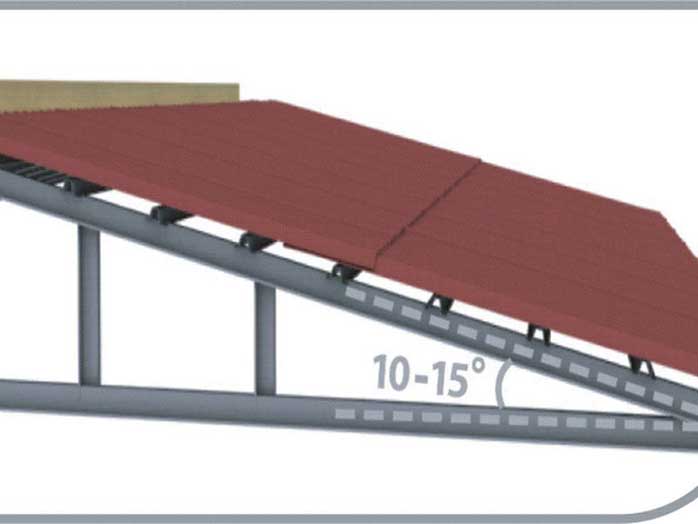

Determine the slope of your roof. The slope is determined by the distance between the highest and lowest points of the roof. This is a very important step when installing roofing panels; as it is the prerequisite for preparing materials; as well as calculating the appropriate roof purlin spacing.

Hướng dẫn thi công lợp mái tôn bao gồm cả việc tính toán khoảng cách xà gồ và diện tích mái

A pitched roof is a roof with a slope of < 8%. The steeper the roof (the steeper the slope), the faster the water drains but the more roofing materials are used. The slope of the roof depends on the material used to make the roof.

The way to calculate the slope of a corrugated iron roof is basically according to the general formula I = H/L.

In which:

- i: Is the symbol indicating the slope;

- H: Is the roof height;

- L: Is the roof length.

Use the slope factors to determine the roof area. Measure the area (length x width) of your house on the ground; then multiply this by the slope (in decimal form). The formula for slope is: length x width x slope. This figure will tell you the area that needs to be covered. For the implementation of the imitation tile roofing method, you calculate the same way.

Khi tính được diện tích mái thì sẽ dễ dàng để chuẩn bị vật liệu cần thiết và dự toán chính xác

5.2. Prepare materials and a work location

Based on the results of calculating the slope and area, you can easily calculate the volume of roofing panels to buy; and other attachments close to the construction; so as not to deviate from the actual and appropriate roofing sheet size.

Before installing roofing sheets, note that you will need a large number of other tools such as a jigsaw; or a metal cutting device, a staple gun, a drill and various drill bits; 1 ¼ inch roofing nails, metal roofing screws, self-sealing wood screws.

To make your installation easy; it is important to have a convenient work area. You will need a large bin for scrap; (old roofing sheets or debris) a place to put tools, scaffolding; or ladders necessary for your installation.

Store the items in the most convenient area and protected from the sun and rain.

5.3. Remove the old roof and repair any damage if it is a home renovation

If you want to replace the roof, start at the highest point; the furthest point and remove all the old shingles, ridge caps; vents, and guards. You should replace all of these with new metal roofing. With metal roofing construction in the case of roof repair, roof replacement; it is necessary to remove the debris of the previous roof.

Reposition the gutters if you want

With the old materials removed, the bare bones of the roof frame or plywood will be exposed. If there is any damage to the roof frame, insulation, ventilation system; repair it immediately.

5.4. Installation, instructions for roofing construction

Step 1: Install the surrounds

The eaves and louvers are the metal strips used to surround the entire perimeter of the roof. Use 1 ¼ inch roofing nails to secure them to the roof. They should overlap the edges of the gutters (if any).

Step 2: Install the Panels

Start from the highest point and work your way to the edge of the roof. Hold the first panel and place it on the roof so that it overhangs the edge by at least ¾ inch. The same goes for cold-rolled shingles.

Use neoprene washer-head screws to secure them. Space the screws about 12 inches apart.

Continue installing the other panels; make sure the edges overlap by at least 1 inch; or as required by the design for adjacent panels. Continue until the entire roof is covered. If you feel the need to use a sealant, place a bead of 100% silicone; or silicone caulk before laying the panels down and make sure the bead is close to the edges of the bottom panel. This will cause the silicone to tighten toward the edges; making the panels more secure.

Installation is the most important step when constructing a corrugated iron roof, the other steps are just preparations in all aspects to support, so you need to be careful and meticulous.

Step 3: Install the joint cover panels

This is the same material as the awning; except that it is placed on the slots on the roof. You should use the roof slot.

The joint cover panel can be bent into a V shape to fit the roof.

Depending on the width of the joint slot, you can use one or two rows of screws.

Step 4: Complete the installation process

- Check again to avoid errors during the installation process.

- Clean up all remaining roofing pieces and screws.

- Notes when constructing and installing corrugated iron roofs

During transportation, unloading and when bringing it to the roof; absolutely do not slide the roof panels to avoid the risk of tearing the plastic bag; (covering standard roof panels with small lengths) leading to scratches; dirty or damaged roof panels.

Only remove the plastic bag after the roofing sheet is placed in the position to be covered on the roof.

When screwing the roof: pay attention to the screwing technique because it must be used frequently; sell the positive screws, perpendicular to the surface of the roofing sheet; (use 6cm long screws and 5cm long screws with 11-wave corrugated iron sheets); with sufficient screwing force, avoid damaging the corrugated iron surface at the screwing position.

When screwing the wall: screw into the negative screws; perpendicular to the surface of the roofing sheet (use 4cm long screws).

Use roof purlins with a minimum thickness of 1.5mm, for civil roofs; should use white painted steel boxes to contribute to increasing the aesthetics of the project.

When cutting the roofing sheet with a cutting machine, absolutely do not let iron chips shoot onto the corrugated iron surface, burning the paint and causing the corrugated iron roof to rust.

When installing corrugated iron roofing, the roof must be cleaned thoroughly; Otherwise, iron filings generated when screwing and other waste (nails, screws, rivets, mortar, etc.) will cause rust on the roof, affecting the aesthetics and lifespan of the corrugated iron roof.

Absolutely do not use abrasive cleaning solutions or solvents such as turpentine, gasoline, kerosene and solvents to clean paint on the surface of corrugated iron roofing sheets.

In case of not using it immediately, the roofing sheets need to be kept in a dry place; placed away from the floor, and the outer nylon layer must not be peeled off.

6. Introducing a reputable design & construction consulting service provider

The importance of construction units is undeniable, their reputation will ensure the quality and aesthetics of your project. Currently, there are many units providing design and construction services to meet the increasing construction needs in our country. Therefore, finding a reputable unit is not easy and requires you to spend time researching. In the selection process, you need to research carefully and ensure that the accompanying unit must have high expertise, many years of experience, have a clearly signed contract, transparent costs, ... To help customers save time searching, Hung Nghiep Phu Construction Investment Company Limited is confident that it will be the best choice for you.

Hung Nghiep Phu Construction Investment Co., Ltd. with the mission of providing the best solutions and services, building a prosperous community with customers, Hung Nghiep Phu is gradually affirming its brand through sincere cooperation, with a leadership team with ethical capacity, creativity, high expertise and strategic vision. Hung Nghiep Phu owns a team of skilled, highly qualified employees who will bring customers the best quality technology.

Hung Nghiep Phu Construction Investment Co., Ltd. - specializes in constructing civil and industrial works. We look forward to accompanying customers in construction projects as well as continuous procedures such as planning diagrams, applying for construction permits, completing procedures, applying for fire prevention and fighting certificates,... If you have any questions or are in need of design, completing procedures, please contact us immediately for free consultation!

>>> See more:

_____________________

CONTACT INFO:

![]() Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

![]() Đường dây nóng: 1800.3368 (Miễn phí)

Đường dây nóng: 1800.3368 (Miễn phí)

![]() Trang web: xaydunghunnghiepphu.com

Trang web: xaydunghunnghiepphu.com

![]() Gmail: kinhdoanh01@xaydunghungnghiepphu.com

Gmail: kinhdoanh01@xaydunghungnghiepphu.com

![]() Address: No. 2034D, Group 22, Phuoc Thai Quarter, Thai Hoa Ward, Tan Uyen City, Binh Duong Province

Address: No. 2034D, Group 22, Phuoc Thai Quarter, Thai Hoa Ward, Tan Uyen City, Binh Duong Province

------

Source: Compiled from the Internet