CONSTRUCTION TECHNIQUES FOR WATERPROOFING CONCRETE CEILINGS

Construction works in Vietnam often use concrete ceilings because of their solidity and sturdiness. However, after a while, concrete ceilings often deteriorate quickly, most notably the appearance of yellow stains, black mold, and blue-gray on the ceiling. Therefore, solutions and methods of waterproofing concrete ceilings need to be applied to ensure the best quality of the construction! Follow Hung Nghiep Phu to follow the article below for more details!

1. What is a concrete ceiling? What is concrete ceiling waterproofing?

Concrete ceilings are a trend in the world of using materials that the project pursues. Concrete materials not only exist in architectural components but also participate in interiors such as tables - chairs, counters, shelves, shelves ... with the role of architectural materials, decorative materials.

Reinforced concrete materials were born in Europe in the late 19th century, a turning point in the history of architecture - construction. Concrete ceilings consist of a mixture of cement mortar with stone or gravel combined with steel placed inside to increase bearing capacity.

With the use of reinforced concrete in concrete ceilings, buildings grow taller, walls and columns become smaller and architectural forms become more diverse. Reinforced concrete is used in the process of creating diverse and changing shapes.

The raw materials that make up reinforced concrete are abundant and easy to exploit and process in nature (sand, gravel, stone, cement, steel), so the cost of reinforced concrete is relatively cheap, and can be widely applied in many locations and terrains with many different types of constructions.

Therefore, waterproofing concrete ceilings will often be used in the process of using civil houses such as current townhouses and villas!

Concrete ceilings have their own beauty because of their roughness and simple colors, typically cement gray. In addition to using real materials, not hidden... in line with the views of some architectural schools. However, to create a beautiful exposed concrete surface is not easy when the construction process requires standard concrete quality and professional workmanship. All underground technical systems located in the concrete must be installed and connected accurately before proceeding with the concrete pouring into the mold.

In addition, if using exposed concrete, the construction process and structure of other architectural components must also comply reasonably, such as doors, railings, roofs, etc. But there is actually a trend of using more and more of this material, which will bring diversity to architectural works and contribute to improving technical level in both design and construction.

2. When is it necessary to waterproof concrete ceilings?

Concrete is a common and necessary material for every house, but during use, concrete ceilings need to be properly waterproofed. When the terrace is stagnant for a long time, it will lead to moisture and water leakage into the house. After that, the ceiling will appear many cracks, discolored, yellowed or some places where water drips and damages the ceiling. That is when we need to waterproof the concrete ceiling.

Nhà dột, cần chống thấm trần nhà bê tông

However, “prevention is better than cure”, do not wait until the ceiling is leaking before rushing to waterproofing measures. You need to find waterproofing contractors, or handle waterproofing measures simultaneously during and immediately after completing the house construction to minimize the phenomenon of seepage and leakage after completing the house.

3. Why do we need to waterproof concrete ceilings?

There are many reasons that lead to the phenomenon of concrete ceilings leaking and peeling. However, we can mention the reasons for waterproofing concrete ceilings as follows:

- Due to poor construction materials, the floor is easily cracked and cracked when it rains. After a few years of using concrete ceilings, there will be cracks in the concrete roof floor due to concrete shrinkage, due to the sudden difference in temperature between sun and rain, expanding in summer and contracting in winter, also known as the phenomenon of "Concrete Thermal Shock".

Hướng dẫn các cách chống thấm trần nhà bê tông mang lại hiệu quả sử dụng tối ưu nhất

- Due to changes in the structure of the materials surrounding the roof, the phenomenon of separation causes seepage. Concrete ceiling cracks due to subsidence, substandard concrete roof steel, poor quality concrete grade.

- The house is waterproofed but still leaks and cracks because: the waterproofing material is not good, does not meet quality assurance, so when exposed to weather, it cannot change in the environment.

Hiện tượng nhà nứt, rò rỉ nước cần chống thấm trần nhà bê tông

- Do not test the water before laying the tiles.

- The drainage system of the terrace is poor, water stagnates, the terrace design is not suitable for repair. Pouring a new concrete floor into the old concrete floor, the leaking position is the joint between the old floor and the new floor (concrete joint).

The above are the main reasons why waterproofing the concrete ceiling is necessary. In addition, there are other reasons leading to concrete ceiling leaks such as arbitrarily changing the structure of the house, renovating the house without consulting the design and construction.

Những cách chống thấm trần nhà bê tông đem lại hiệu quả

4. Consequences of not waterproofing the ceiling can be

Construction projects that have been in contact with water for a long time often lead to leaks in many areas that have to be exposed to water for a long time. Especially the ceiling, if it leaks, it will have a strong impact on the entire house such as mold, destruction of the concrete structure, affecting health, endangering human life... Therefore, when signs of mold and leaks appear, we need to waterproof the ceiling immediately. Because when the roof leaks, it will affect the aesthetics of the whole house as well as possibly affect the family's living process.

In particular, the ceiling is also a component that is often directly affected by the environment and weather, so the possibility of wear and tear and leaks easily occurs. Therefore, to minimize the consequences of seepage, leakage, and cracks from the ceiling, you need to know how to waterproof the ceiling to bring the highest efficiency.

5. Effective measures and ways to waterproof concrete ceilings

We have many ways to waterproof concrete ceilings, but in the content below, we will guide you through 3 ways to waterproof concrete ceilings as follows:

- Waterproofing concrete ceilings by applying Sikaproof Membrane.

Chống thấm trần nhà bê tông

Sikaproof Membrane is a one-component, cold-applied, water-based, modified bitumen polymer liquid membrane waterproofing material. Sikaproof Membrane acts as a subsoil waterproofing layer for concrete and plaster surfaces, used for waterproofing flat roofs, balconies, basements, walls, etc.

Sikaproof Membrane is a material that can be easily purchased and used in the process of waterproofing concrete ceilings. This material has a low cost with many advantages such as easy application by brush or spray or quick drying to form a durable and flexible coating; excellent adhesion and crack sealing. The design of this material is easy to use on old and new structures as well as does not contain solvents; odorless and non-sticky.

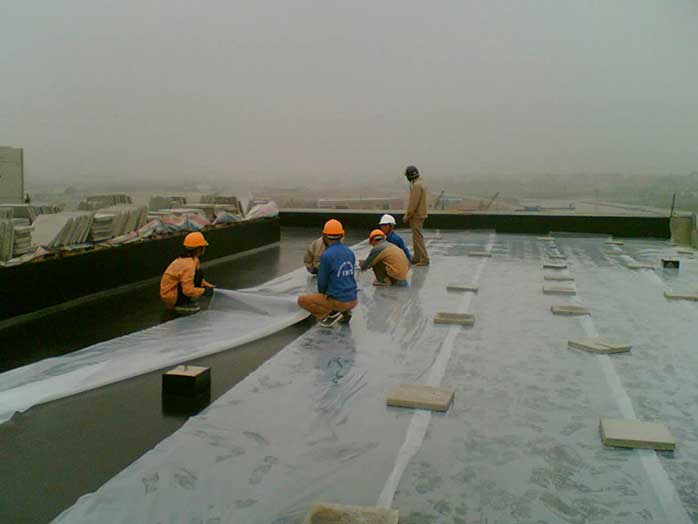

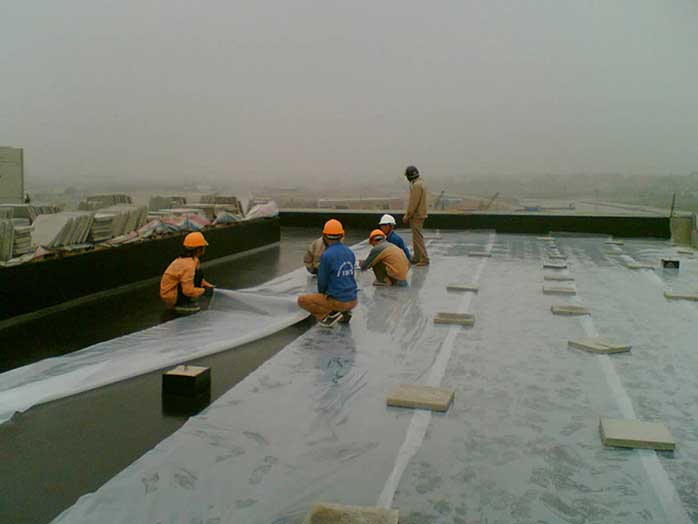

- Waterproofing concrete ceilings by applying self-adhesive or hot-melt waterproofing membranes.

Another way to waterproof concrete ceilings that many households use is to apply cold-applied or hot-melt waterproofing membranes.

Chống thấm trần nhà bê tông bằng màng chống thấm tự dính

Self-adhesive waterproofing membranes are usually in sheet form; and are covered with a thin layer of HDPE film on the surface. HDPE is High Density Poly Ethylene; is a type of plastic that is very heat-resistant in liquid environments; as well as solutions that are often encountered on water supply and drainage lines and soil. It does not rust and is not affected by solutions such as salt, acid and alkali, even in acid rain. The other side is protected by a layer of silicon film.

Waterproofing with self-adhesive membranes is effective in completely preventing leaks; simple and easy construction. We just need to peel off the silicon layer to be able to stick it directly, safely; and faster than heat-welded waterproofing membranes; because there is no need to use heat to create adhesion with extremely good adhesion; on the construction surface when the temperature changes. This material can be widely used in waterproofing concrete ceilings; waterproofing bridges, tunnels, sewers, etc. Waterproofing with adhesive membranes has the advantage of being safe for human health; and environmentally friendly, no toxic chemicals causing pollution; not picky about construction materials.

The disadvantage of self-adhesive membranes in waterproofing concrete ceilings will appear joints between the membrane panels. Compared to some other materials; this is not the solution that brings the highest durability and longevity.

In contrast to the above material line, waterproofing concrete ceilings; often using hot-melt membranes is mentioned with different points. Hot-melt waterproof membrane; also known as Bitumen hot-melt waterproof membrane is a flexible waterproof membrane; produced from a mixture rich in bitumen and selected APP polymers (Atactic Poly Propylene); has the ability to withstand heat, UV rays and high waterproofing ability.

Advantages of hot-melt membranes in waterproofing construction; as well as waterproofing with self-adhesive membranes such as leak-proofing; almost absolute for the construction surface; safe, friendly to health and the surrounding environment, non-toxic. With high applicability: waterproofing adjacent wall joints; waterproofing terraces, waterproofing water reservoirs, water tanks, etc.

Hướng dẫn cách chống thấm sàn bê tông mang lại hiệu quả sử dụng

The disadvantage of the hot-melt membrane waterproofing technique is that the construction is complicated; especially at the joints of the membrane panels. In addition, it also requires heating and hot-melt techniques to create adhesion. And the lifespan and durability are only equal to self-adhesive membranes.

- Waterproofing concrete ceilings with asphalt

When waterproofing concrete ceilings with asphalt, we need to pay attention but need to ensure that the surface is cleaned with a primer; Asphalt-based primer (free of dirt and dry).

Hướng dẫn các cách chống thấm trần nhà bê tông đem lại hiệu quả tối ưu nhất

If using asphalt shingles, they must be glued straight, not folded. The adjacent side flaps overlap each other by 10cm, the last flap overlaps by 15cm. At the intersections with the wall, they must be glued to the wall by 15cm.

Reinforce weak points such as the base of the wall junction with the floor; drain pipe collar, subsidence gap with a layer of asphalt-based primer.

Note: How to waterproof different types of roofs:

- For tile or corrugated iron roofs

In the case of corrugated iron or tile roofs, the cause of water seepage is due to broken tiles; nail marks or at joints that lead to water seepage when the rainy season comes.

To waterproof this type of roof, you just need to adjust the tile roof; or use a mixture of cement, sand; other waterproofing additives and then apply a thick layer on the leaking surface.

In the case of corrugated iron roofs, you use screws to screw them tightly; to prevent water from seeping in underneath. In addition, you can combine with waterproof paint; to paint on the screw holes on the roof will help waterproof more effectively.

- For flat roofs

Normally, flat roofs will leak less, in case of leakage; the cause is because the roofing material has tiny holes; which are invisible to the naked eye. Therefore, after a period of time under the influence of weather conditions; making these holes larger, causing your roof to leak water.

In this case, you can use waterproof paint to paint over the leaking ceiling; the advantage of this type of paint is that it dries quickly and helps waterproof effectively.

6. Step-by-step guide to waterproofing concrete ceilings

Step 1: Surface preparation:

Good surface preparation is important to achieve optimal waterproofing quality. We need to clean the surface of the terrace, roof floor, balcony. Concrete ceilings are often dirty during use; moss accumulates, leading to water leakage, so waterproofing concrete ceilings is very necessary. Therefore, the first thing in the waterproofing process is that the surface must be solid; hard, clean, free of dirt, oil, grease or other dirt. Then, construction directly on the concrete surface is the most optimal way; because the concrete is hard, the durability of the waterproof layer will be very high.

For houses when building, if we do not pay attention to issues such as waterproofing, right from the beginning of construction; the infrastructure will be seriously affected because it can lead to peeling paint; water seepage on the walls will cause loss of aesthetics and damage to the structural connections of the house.

Step 2: Waterproofing the concrete ceiling

Create a thin layer of mortar and sweep it onto the concrete floor surface; to fill in the cracks of the terrace. There are many types of mortar on the market; you can choose the type of mortar during use to suit your needs. Then also sweep 2 layers onto the concrete surface; wait for the first layer to dry before sweeping the second layer, each layer is 1-2 hours apart.

Hướng dẫn quy trình chống thấm trần nhà bê tông đem lại hiệu quả sử dụng

Step 3: Effective waterproofing of concrete ceilings

Wait 3-4 hours after the waterproof mortar layer dries; we will spray the waterproof solution on the entire concrete floor; and the brick wall of the terrace. Note that you should spray 2 layers, each layer is 3-4 minutes apart; spray evenly and ensure the floor surface is wet. Spray the wall about 15-20 cm high.

Hướng dân các bước chống thấm trần nhà bê tông mang lại hiệu quả

Step 4: Finally, we check the work results and conduct regular terrace maintenance.

7. Introducing a reputable design & construction consulting service provider

The importance of construction units is undeniable, their reputation will ensure the quality and aesthetics of your project. Currently, there are many units providing design and construction services to meet the increasing construction needs in our country. Therefore, finding a reputable unit is not easy and requires you to spend time researching. In the selection process, you need to research carefully and ensure that the accompanying unit must have high expertise, many years of experience, have a clearly signed contract, transparent costs, ... To help customers save time searching, Hung Nghiep Phu Construction Investment Co., Ltd. is confident that it will be the best choice for you.

Hung Nghiep Phu Construction Investment Co., Ltd. with the mission of providing the best solutions and services, building a prosperous community with customers, Hung Nghiep Phu is gradually affirming its brand through sincere cooperation, with a leadership team with ethical capacity, creativity, high expertise and strategic vision. Hung Nghiep Phu owns a team of skilled, highly qualified employees who will bring customers the best quality technology.

Hung Nghiep Phu Construction Investment Co., Ltd. - specializes in constructing civil and industrial works. We look forward to accompanying customers in construction projects as well as continuous procedures such as planning diagrams, applying for construction permits, completing procedures, applying for fire prevention and fighting certificates,... If you have any questions or are in need of design, completing procedures, please contact us immediately for free consultation!

>>> See more:

_____________________

CONTACT INFO:

![]() Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

![]() Hotline: 1800.3368 (Miễn phí)

Hotline: 1800.3368 (Miễn phí)

![]() Website: xaydunghunnghiepphu.com

Website: xaydunghunnghiepphu.com

![]() Gmail: kinhdoanh01@xaydunghungnghiepphu.com

Gmail: kinhdoanh01@xaydunghungnghiepphu.com

![]() Address: No. 2034D, Group 22, Phuoc Thai Hamlet, Thai Hoa Ward, Tan Uyen City, Binh Duong Province

Address: No. 2034D, Group 22, Phuoc Thai Hamlet, Thai Hoa Ward, Tan Uyen City, Binh Duong Province

------

Source: Compiled from the Internet