INDUSTRIAL FACTORY HORIZONTAL FRAME STRUCTURE

The horizontal frame structure is an important part in the design and construction of industrial factories. The horizontal frame not only bears the load but also determines the stability, durability and resistance to environmental factors such as wind and earthquakes. This article will analyze in detail the structure, function, advantages and construction process of the horizontal frame structure of industrial factories.

1. Horizontal frame structure

1.1. Main components

- Column: The column is the vertical part of the frame, bearing the load from the roof and other elements. The column is usually made of steel or reinforced concrete, depending on the design requirements. The column must be able to withstand large loads and be placed at an optimal distance apart to ensure stability for the entire structure.

- Rafter (or crossbar): The rafter is the horizontal part, connecting the columns, with the function of bearing the load from the roof to the column. The rafter is usually made of I-shaped steel, H-shaped steel, or other types of steel. The rafter must ensure good bearing capacity and not be deformed when carrying large loads.

- Roof: The factory roof is usually designed with a reasonable slope to drain rainwater and ensure that water does not accumulate. The roof can be made of corrugated iron, panels or concrete, depending on the nature of the factory and usage requirements.

- Floor: The floor of the factory is usually made of reinforced concrete, with a large load-bearing capacity to meet the needs of transporting goods and operating machinery in the factory.

1.2. Structural details

- Connections: The parts of the horizontal frame are connected together by welds, bolts or rivets, ensuring the strength and stability of the structure.

- Bracing: Bracing is a diagonal connecting bar between columns and trusses, helping to increase the stiffness of the structure and minimize vibration when there is a large load or strong wind.

2. Function of the horizontal frame

- Bearing loads: The horizontal frame structure has the function of bearing loads from the roof and other factors such as wind, earthquakes, and static loads from machinery and goods inside the workshop.

- Creating working space: The horizontal frame structure helps create open space, allowing flexible arrangement of machinery and production lines.

- Safety: The horizontal frame structure must be designed and constructed according to technical standards to ensure the safety of workers and equipment in the workshop.

3. Advantages of cross-frame structure

- Flexibility: With the horizontal frame design, the factory can easily change its function or rearrange the working areas without affecting the main structure.

- Cost savings: The use of steel or reinforced concrete materials helps save construction costs compared to other types of structures. At the same time, construction time is also faster, minimizing labor costs.

- High durability: The horizontal frame structure has good resistance to external factors such as wind, rain, and earthquakes, ensuring the safety of the project throughout its use.

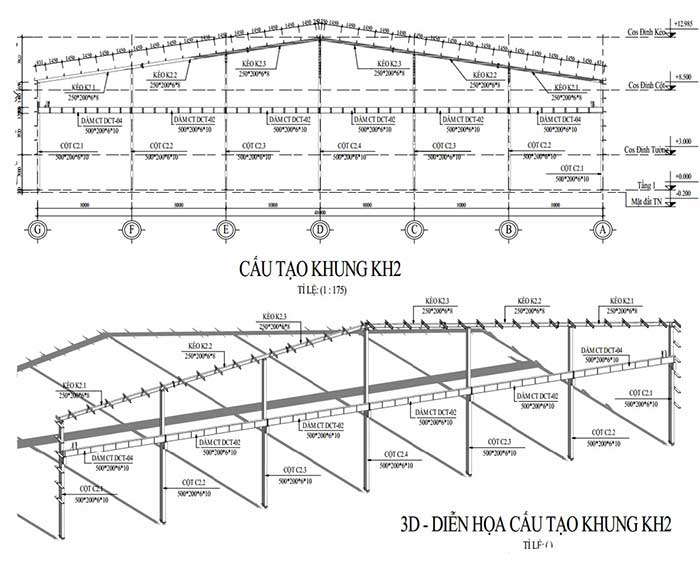

4. Horizontal frame diagram

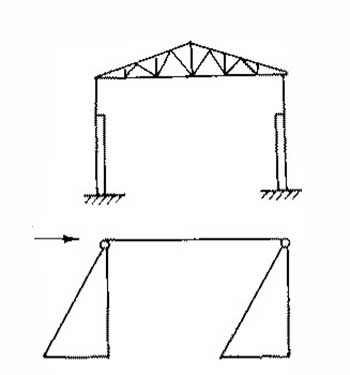

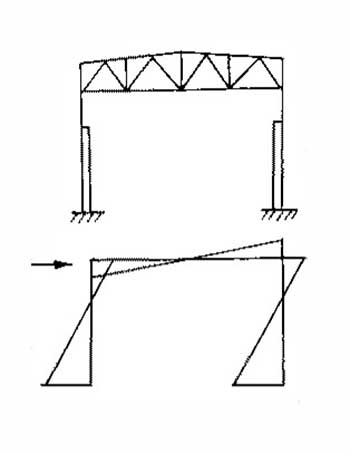

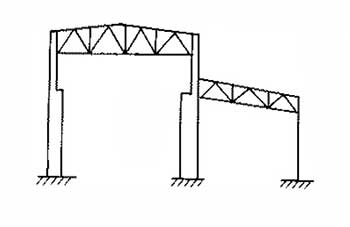

- The cross-frame has one or more spans, suitable for the cross-section of the house.

- The connection between the truss and columns can be hinged or rigid.

- Hinged connections are commonly used because of their convenience in fabrication and assembly.

- Jointed frames have low stiffness, so they are suitable for light crane workshops with small heights.

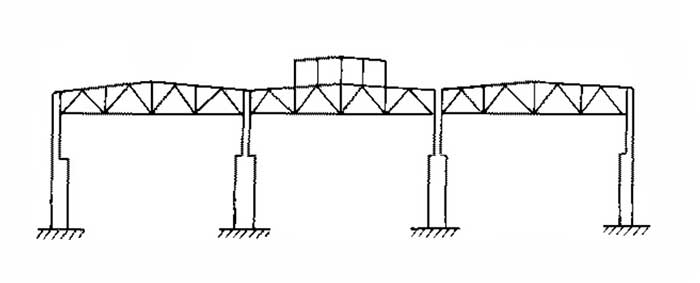

- Multi-span frames often use jointed connections because the stiffness of the frame itself is large, and it is difficult to solve the structure of the rigid nodes in the columns between the frames.

- Composite frames with reinforced concrete columns always use jointed connections, with the scaffolding placed freely on the top of the column.

Rigid connections create great stiffness for the frame, applied when high stiffness is required such as for single-span workshops with large crane loads or when the working mode is heavy.

The truss of the horizontal frame is triangular, or trapezoidal (two slopes) or parallel wings.

The triangular truss is only applicable to the joint frame, the latter two types are used for both the joint frame and the rigid frame.

The columns of the building with the crane are usually stepped columns, the cross-section changes from the crane shoulder.

When the crane is light (Q < 15-20t), it is recommended to use columns with a constant cross-section, with a simpler structure.

The multi-span frame of the factory can have different shapes depending on the height of each span and the way to get light above, the way to drain the roof.

When the height of the house between two adjacent spans differs greatly, for example, from 1.8m or more. Due to the requirement of arranging a bridge crane or to get light from the side, use frames with different heights as shown below (the frames at the border spans can have two sloping roofs, draining water inside or have one sloping roof, draining water outside).

5. Main dimensions of the horizontal frame of the factory structure

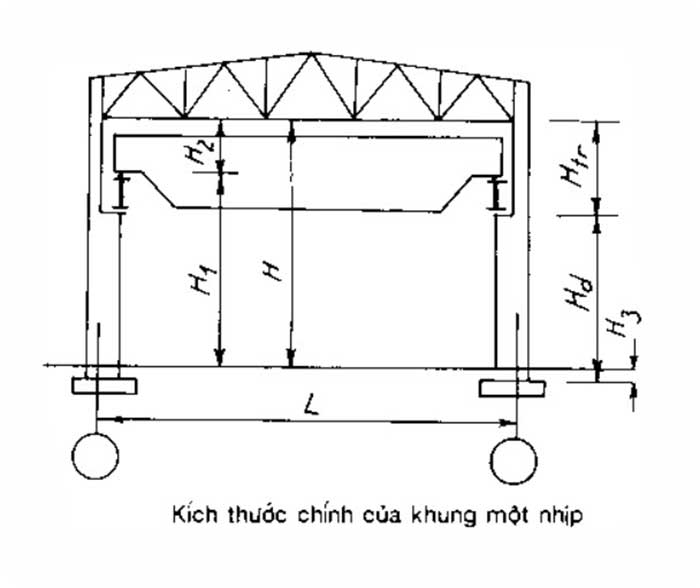

The cross-frame has main horizontal dimensions related to the width of the house (frame span) and vertical dimensions related to the useful height of the house.

- Horizontal dimensions

The basic dimension is the frame span L (distance between longitudinal positioning shafts). The span L has a module of 3m when the span is less than 18m and a module of 6m when the span is larger.

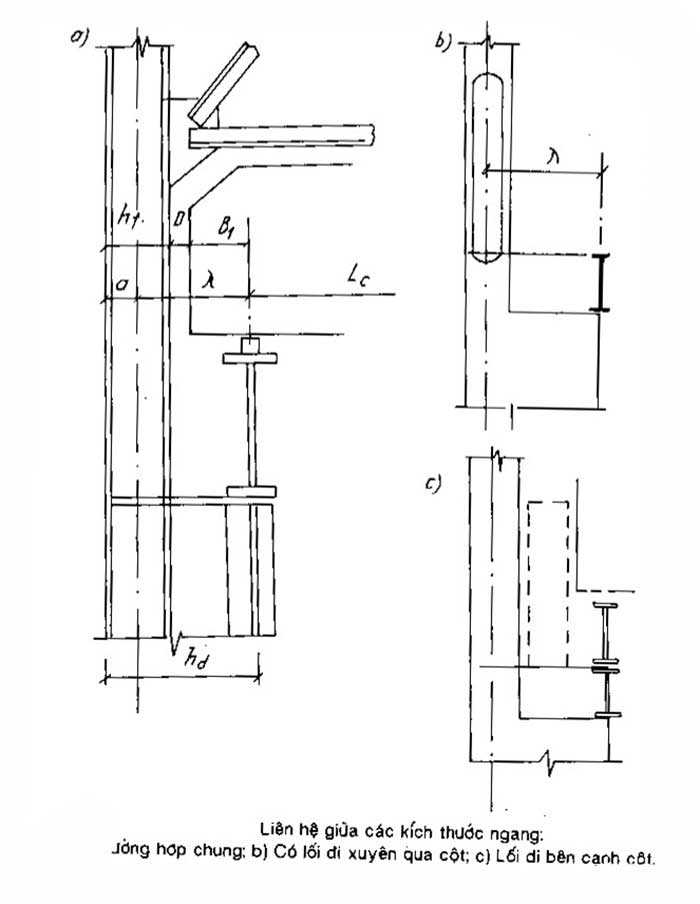

At the edge column, the positioning shaft is a distance of a = 250 or 500mm from the outer edge of the column or coincides with the edge of the column (a = 0).

- The case of a = 0 applies to factories without cranes or light cranes, with a crane capacity of 30t or less.

- The distance a = 500mm applies to buildings with cranes Q>75t or cranes with heavy working mode requiring a walkway for people to walk on the crane girder surface.

- In the remaining cases, a = 250mm.

The width of the upper part of the stepped column ht, due to the stiffness requirement, is taken at about 1/10 to 1/12 of the height of the upper column Ht, which is about 400 - 1000mm. The width of 1000mm applies when it is necessary to make a hole for people to walk through the column belly. Hole size 1800 x 400mm.

For the middle column of a multi-span frame, the positioning axis coincides with the column axis.

In order for the crane to move without touching the column, the distance λ from the rail axis to the positioning axis must be large enough: λ >= B1+(Ht - a) + D.

- B1: The head of the crane outside the rail, taken according to the crane catalog, is about 200 - 500mm.

- D is the safety gap between the crane and the inside of the column, taken as 60 - 75mm.

- The span of the crane Lc is the distance between the two rail centers: Lc=L - 2λ

Lc has a module of 0.5m, so λ must be taken as an even 250mm. Therefore, λ has the following values:

- λ=750mm when the building has a crane Q <= 75t.

- λ=1000mm when the crane is larger than 75t or when there is a passage through the column.

- λ=1250mm when the crane is very heavy, or when there is a walkway outside the column.

The width of the lower column hd, due to the stiffness condition, should not be less than (1/1 - 1/20)H where H is the total height of the column.

The axis of the column branch supporting the crane girder usually coincides with the axis of the crane girder, then the width of the lower column is Hd = a + λ, which is equal to 750,1000,1250,...mmm. For frames using columns of constant cross-section, the width of the column must not be less than 1/25H.

- Vertical dimensions of the factory structure

The basic dimension is the minimum distance H1 from the ground surface to the crane rail surface; H1 is given in the design task based on the manufacturing technology.

Dimension H2 from the rail surface to the bottom of the load-bearing structure (lower wing of the truss) is determined by the crane gabarit: H2 = (Hc + 100)+ f.

- Hc: Crane gabarit dimension, from the rail surface to the highest point of the crane trolley;

- 100: Safety clearance between the trolley and the structure;

- f: Additional clearance, considering the deflection of the structure, the arrangement of the tie bar is taken as 200 - 400mm;

- Dimension H2 is taken as 200mm.

Factory height, from the floor to the bottom of the truss: H = H1 + H2

- The size H according to the QPXD 57 - 73 standard is taken as a multiple of 1.2m when smaller than 10.m and of 1.8m when larger.

The actual size of the column above Ht from the crane beam shoulder to the truss: Ht = H2 + Hdct + Hr

- Hdct is the height of the crane beam, taken according to the typical design or given roughly (1/8 - 1/10) of the beam span (column step).

- Hr is the height of the rail and pad, roughly taken as 200mm.

The height of the lower part of the column is calculated from the base plate (from the foundation surface) to the change of cross-section Hd = H - Ht + H3

- H3 = 600 - 1000mm of the column buried below the ground level.

The height of the column at the top of the truss is equal to the height of the truss at the support. The trapezoidal truss usually takes the overall height at the support as 2250mm, the parallel truss is 3150mm.

For multi-span frames with the same height, the vertical and horizontal dimensions of the edge column and the middle column are taken as presented above, the width of the lower part of the middle column is 2λ (use the larger value of λ of the span).

For multi-span frames with different heights, the vertical dimensions of each span H, H1, H2, H’, H1′, H2′ are determined separately as above. The width of the lower part of the middle column is hđ = λ + λ’, the column is not symmetrical to the positioning axis.

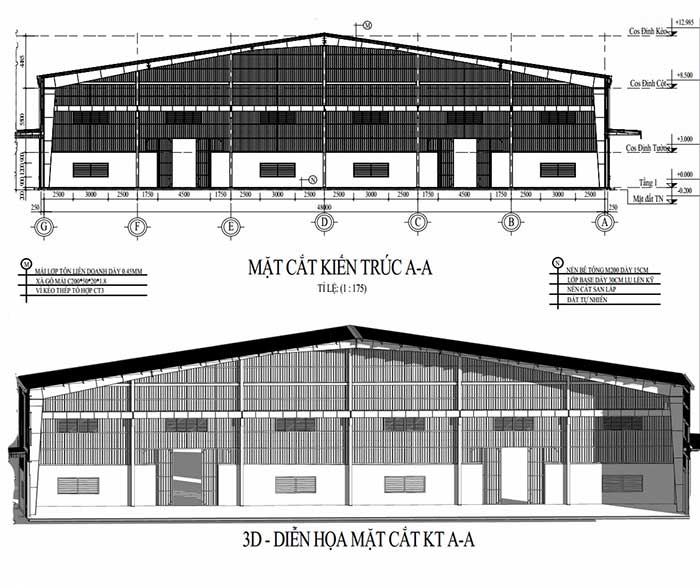

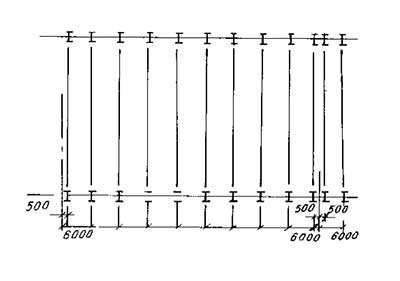

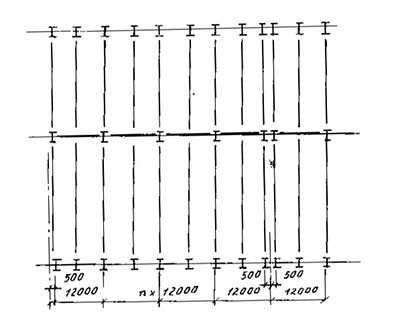

6. Industrial building horizontal frame layout

The horizontal frame of the industrial building is arranged horizontally in the house, the frame columns form a column grid:

- The frame step (the distance between the vertical frames of the house) has a module of 6m;

- The edge column step is usually 6m to easily solve the covering structure;

- The middle column step can be 6m or 12m or even larger;

- In the case of avoiding the middle column, in addition to the complete frames consisting of all the columns, there are incomplete frames (the frame in the middle row of columns is placed on the truss support frame).

When the house has a large floor area, to reduce stress due to temperature changes. The house is divided by thermal slots into separate blocks; called thermal blocks. The distance between thermal slots is specified as follows:

- With a full steel frame, the vertical distance of the house is 200m, the horizontal distance of the house is 120m;

- With a mixed frame, the above dimensions are only 45m;

- The axis of the horizontal thermal slot coincides with the positioning axis. The column at the thermal slot as well as at the gable end of the house must be moved inward by 500mm. The purpose is to keep the enclosing structure uniform in size.

7. Construction process

7.1. Preparation before construction

- Design and drawing: Before construction, it is necessary to have detailed design drawings for the horizontal frame structure, including parameters on size, materials and construction methods.

- Material selection: Choose materials suitable for the technical requirements and properties of the project. For columns and trusses, high-quality steel or reinforced concrete is often used.

7.2. Construction of the structure

- Erection of columns: First, erect the columns in predetermined positions. The columns need to be positioned accurately and fixed with concrete piles or steel bases.

- Rafter installation: After the columns have been fixed, proceed to install the trusses. The trusses must be firmly connected to the columns to ensure stability for the entire structure.

- Roof and floor construction: Finally, install the roof and floor for the factory. Ensure that the details are done accurately, with no gaps or gaps between the material panels.

7.3. Inspection and acceptance

- Quality inspection: After construction is completed, it is necessary to inspect the entire horizontal frame structure to ensure that there are no errors in size, verticality and strength.

- Record of acceptance: Prepare a record of acceptance for each construction item, recording the technical parameters and condition of the structure as a basis for future monitoring and maintenance.

The horizontal frame structure of an industrial factory plays an important role in creating a safe and efficient working space. With outstanding advantages in flexibility, durability and load-bearing capacity, the horizontal frame is the first choice for modern industrial factories. Strict adherence to the design and construction process will help ensure the quality and safety of the project throughout its use.

8. Introducing a reputable design & construction consulting service provider

The importance of construction units is undeniable, their reputation will ensure the quality and aesthetics of your project. Currently, there are many units providing design and construction services to meet the increasing construction needs in our country. Therefore, finding a reputable unit is not easy and requires you to spend time researching. In the selection process, you need to research carefully and ensure that the accompanying unit must have high expertise, many years of experience, have a clearly signed contract, transparent costs, ... To help customers save time searching, Hung Nghiep Phu Construction Investment Co., Ltd. is confident that it will be the best choice for you.

Hung Nghiep Phu Construction Investment Co., Ltd. with the mission of providing the best solutions and services, building a prosperous community with customers, Hung Nghiep Phu is gradually affirming its brand through sincere cooperation, with a leadership team with ethical capacity, creativity, high expertise and strategic vision. Hung Nghiep Phu owns a team of skilled, highly qualified employees who will bring customers the best quality technology.

Hung Nghiep Phu Construction Investment Co., Ltd. - specializes in constructing civil and industrial works. We look forward to accompanying customers in construction projects as well as continuous procedures such as planning diagrams, applying for construction permits, completing procedures, applying for fire prevention and fighting certificates, ... If you have any questions or are in need of design, completing procedures, please contact us immediately for free consultation!

>>> See more:

_____________________

CONTACT INFO:

![]() Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

![]() Hotline: 1800.3368 (Miễn phí)

Hotline: 1800.3368 (Miễn phí)

![]() Website: xaydunghungnghiepphu.com

Website: xaydunghungnghiepphu.com

![]() Gmail: kinhdoanh01@xaydunghungnghiepphu.com

Gmail: kinhdoanh01@xaydunghungnghiepphu.com

![]() Address: No. 2034D, Group 22, Phuoc Thai Hamlet, Thai Hoa Ward, Tan Uyen City, Binh Duong Province

Address: No. 2034D, Group 22, Phuoc Thai Hamlet, Thai Hoa Ward, Tan Uyen City, Binh Duong Province

------

Source: Compiled from the Internet