CONSTRUCTION REGULATIONS FOR ACCEPTANCE OF FORMWORK AND SCAFFOLDING WORK

Formwork and scaffolding must be designed and constructed to ensure rigidity, stability, ease of disassembly and assembly, and to avoid difficulties in placing reinforcement, pouring and compacting concrete.

Formwork must be tightly fitted to prevent loss of cement water when pouring and compacting concrete, and to protect newly poured concrete from the effects of weather.

Formwork and scaffolding must be fabricated and assembled to ensure the correct shape and size of the structure according to design regulations.

Formwork and scaffolding can be manufactured at the factory or processed on site. Standard types of formwork and scaffolding are used according to the instructions of the manufacturing unit.

1. Construction materials for formwork and scaffolding.

Scaffolding formwork can be made of wood, raft, steel, precast concrete or plastic. Scaffolding can use bamboo, rattan and reed.

Choosing any material for scaffolding formwork must be based on specific conditions and economic efficiency.

Wood used for scaffolding formwork must comply with the construction wood standard TCVN 1075: 1971 and current standards, and can also use non-standard wood.

Metal scaffolding formwork should be used to be suitable for the ability to rotate many times for different types of structures.

2. Design and construction of formwork and scaffolding

Arch formwork and beams with spans greater than 4m must be designed with a construction camber. The camber value is calculated according to the formula:

ƒ= 3L/1000

In which: L is the span, in m.

The load-bearing parts of the scaffolding should limit the number of connecting bars. The joints should not be arranged on the same cross-section and in positions that bear large loads.

The braces need to be calculated and arranged appropriately to stabilize the entire formwork scaffolding system.

2.1 Erection and construction of formwork and scaffolding.

The installation of formwork and scaffolding must ensure the following requirements:

- The formwork surface in contact with the concrete must be non-stick;

- The side formwork of wall, floor, beam and column structures should be installed in a way that is suitable for early dismantling without affecting the remaining formwork and scaffolding for support (such as formwork for the bottom of beams, floors and columns);

- The scaffolding support must be firmly placed on a hard surface, not slipping and not deformed when subjected to loads and impacts during construction.

When assembling the formwork, there must be surveying markers or appropriate measures to facilitate the inspection of the axis and elevation of the structures.

When stabilizing the formwork with straps and anchors, it is necessary to calculate and determine the quantity and position to keep the formwork system stable when bearing the load and impact during construction.

During the process of assembling the formwork, it is necessary to construct a number of suitable holes at the bottom so that when cleaning the surface, water and dirt have a place to escape. Before pouring concrete, these holes are sealed.

2.2 Check and accept the work of formwork and scaffolding installation.

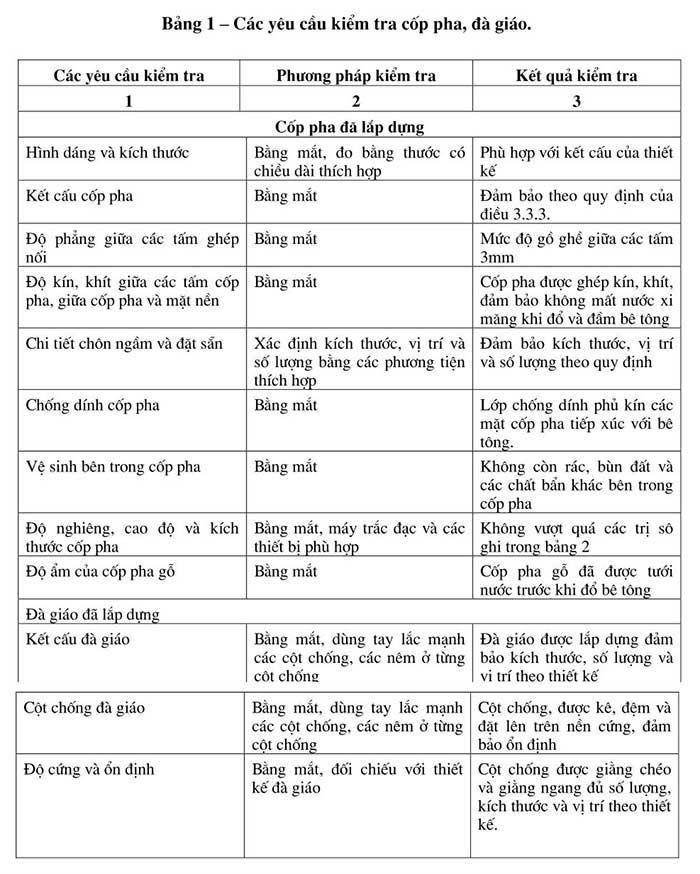

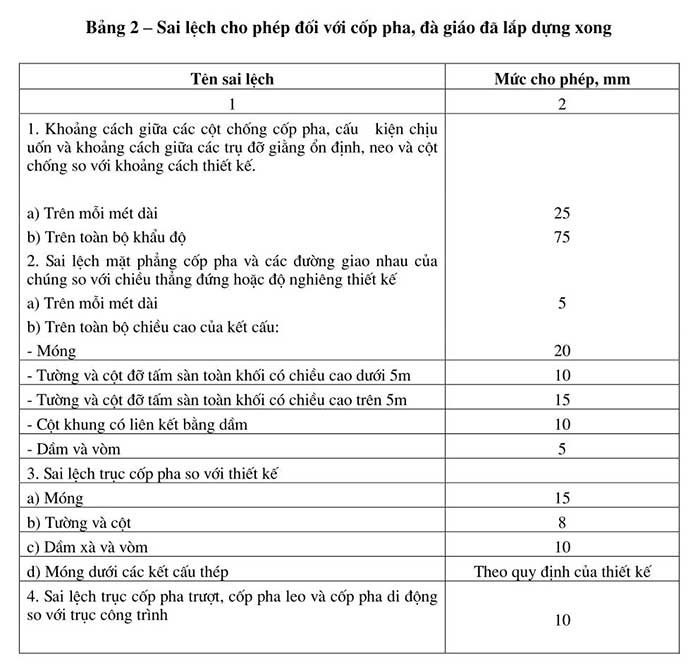

Formwork and scaffolding after erection must be inspected according to the requirements in Table 1, the deviations must not exceed the values recorded in Table 2.

Acceptance of formwork and scaffolding installation work is carried out at the site; combined with assessment and review of inspection results according to the regulations in Table 1 and deviations not exceeding the values recorded in Table 2.

3. Dismantle formwork and scaffolding

Formwork and scaffolding can only be removed when the concrete reaches strength; it is necessary to design the structure to withstand its own weight; and other loads during the following construction phase. When removing formwork and scaffolding, it is necessary to avoid causing sudden stress; or strong impacts that damage the concrete structure

Parts of formwork and scaffolding that are no longer load-bearing after the concrete has solidified; (such as side formwork of beams, wall columns) can be removed; concrete reaches a strength of over 50N/cm2….

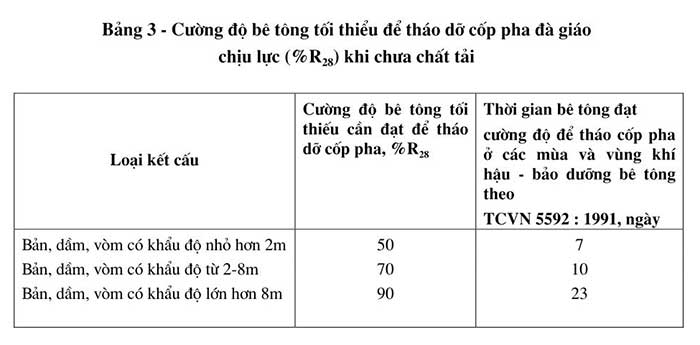

For formwork and scaffolding that bear the load of structures (beam bottom, floor, support columns); if there are no special instructions in the design, they can be removed; when the concrete reaches the strength values listed in Table 3.

For overhang, cantilever, and se-no structures, only support columns can be removed; and bottom formwork when the concrete strength reaches the design grade; and there is an anti-overturning weight object.

When dismantling formwork and scaffolding on monolithic concrete floor slabs of multi-storey buildings, the following should be done:

-

Retain all scaffolding and props on the slab adjacent to the slab to be poured;

Remove each formwork prop from the slab below; and retain “safety” props 3m apart under beams with spans greater than 4m.

For construction works in earthquake areas; and for special works; the concrete strength value required to remove the formwork is specified by the design.

The loading of partial loads on the structure after removing the formwork and scaffolding; must be calculated according to the achieved concrete strength, the type of structure; and the load characteristics to avoid cracks; and other damage to the structure.

The loading of the entire structure after removing the formwork and scaffolding; must only be carried out when the concrete has reached the design strength.

Note:

-

The values in the table do not take into account the effects of additives.

For structures with spans less than 2m, the minimum concrete strength required to remove formwork is 50% R but must not be less than 80N/cm2.

4. Introducing a reputable design & construction consulting service provider

The importance of construction units is undeniable, their reputation will ensure the quality and aesthetics of your project. Currently, there are many units providing design and construction services to meet the increasing construction needs in our country. Therefore, finding a reputable unit is not easy and requires you to spend time researching. In the selection process, you need to research carefully and ensure that the accompanying unit must have high expertise, many years of experience, have a clearly signed contract, transparent costs, ... To help customers save time searching, Hung Nghiep Phu Construction Investment Co., Ltd. is confident that it will be the best choice for you.

Hung Nghiep Phu Construction Investment Co., Ltd. with the mission of providing the best solutions and services, building a prosperous community with customers, Hung Nghiep Phu is gradually affirming its brand through sincere cooperation, with a leadership team with ethical capacity, creativity, high expertise and strategic vision. Hung Nghiep Phu owns a team of skilled, highly qualified employees who will bring customers the best quality technology.

Hung Nghiep Phu Construction Investment Co., Ltd. - specializes in constructing civil and industrial works. We look forward to accompanying customers in construction projects as well as continuous procedures such as planning diagrams, applying for construction permits, completing procedures, applying for fire prevention and fighting certificates, ... If you have any questions or are in need of design, completing procedures, please contact us immediately for free consultation!

>>> See more:

_____________________

THÔNG TIN LIÊN HỆ:

![]() Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

![]() Hotline: 1800.3368 (Miễn phí)

Hotline: 1800.3368 (Miễn phí)

![]() Website: xaydunghunnghiepphu.com

Website: xaydunghunnghiepphu.com

![]() Gmail: kinhdoanh01@xaydunghungnghiepphu.com

Gmail: kinhdoanh01@xaydunghungnghiepphu.com

![]() Address: No. 2034D, Group 22, Phuoc Thai Quarter, Thai Hoa Ward, Tan Uyen City, Binh Duong Province

Address: No. 2034D, Group 22, Phuoc Thai Quarter, Thai Hoa Ward, Tan Uyen City, Binh Duong Province

------

Source: Compiled from the Internet