TECHNICAL PROCEDURE FOR CONSTRUCTION AND ACCEPTANCE OF CLADDING WORK

Main technical requirements and instructions for the construction, inspection and acceptance of the quality of cladding work in civil and industrial construction works. Follow Hung Nghiep Phu to read the article below for more details on "technical requirements, construction procedures and acceptance of cladding work"!

1. Technical requirements

Protective cladding or decorative cladding should be carried out after the completion of the structural construction work.

Cladding on prefabricated structures can be carried out before or after the erection of the structure and depends on the characteristics of the cladding materials, the technological process of manufacturing the structure and the sequence of work specified in the construction design.

Cladding materials are types of tiles and stones that must satisfy the technical requirements specified in the standards TCVN 6414:1998, TCVN 6884:2001, TCVN 4732:1989, TCVN 6883:2001. Depending on the size, weight and type of cladding materials, the properties, flatness of the cladding base, the cladding location and the characteristics of the construction, the appropriate cladding method should be selected.

- Common cladding methods include:

- Cement-sand mortar cladding;

- Glue cladding;

- Cladding with brackets, hooks, bolts, screws, etc.

Before cladding, it is necessary to complete the installation of underground technical networks, details specified for placement in the wall for water supply and drainage systems, electricity, telephone, television, gas supply, air conditioning, computer cables, etc. and other related works to prevent any collisions and vibrations that may cause damage or affect the quality of the cladding.

The surface of the structure that is cladding or protective cladding in the vertical direction must not be tilted beyond the allowable value specified in the standards TCVN 4085:1985, TCVN 4453:1995, TCVN 4452:1987.

Before cladding the interior of the building, it is necessary to complete the roofing and waterproofing of the covering structures above the cladding area, the installation of window and door frames as well as other related works.

It is necessary to check the flatness of the cladding surface before flat cladding construction. If the tiling surface has a concavity greater than 15mm, it must be plastered flat with cement-sand mortar. The concavity of the tiling surface when tiling with glue must be less than or equal to 3mm when checked with a 2m long ruler.

Only tiling on a tiling surface with a flat plaster layer when the strength of the plaster layer has reached at least 75% of the design mortar grade. The plaster layer must ensure good adhesion to the plastered surface. When tiling with cement-sand mortar, only tiles with a weight of less than or equal to 20 kg/m2 should be tiled.

Before tiling the outside of locations where technical pipes run through such as ventilation pipes, air ducts, smoke vents, channels for refrigeration equipment and places where the temperature changes frequently, it is necessary to wrap around the tiling structure a layer of steel mesh with a diameter of 1 mm before plastering. The mesh must extend beyond the range of the technical pipes by at least 20cm.

If there are no specific design instructions, before tiling, it is necessary to calculate and determine the reasonable position of the tiles so that the number of cut pieces is the smallest and arranged in easily hidden positions. If the tiling material has a pattern, it is necessary to choose the position of the tiles to match the decorative pattern and color.

When tiling the exterior of the building, there should be measures to prevent water intrusion or environmental erosion that affects the uniformity and color of the tiling material.

When tiling large natural or artificial stone panels weighing over 5kg, it is recommended to use metal hooks or a hanging system with screws and adjustable bolts to firmly attach to the tiling surface. In the case of tiling the exterior of the building using these methods, there must be measures to waterproof the exterior of the wall before tiling.

Mortar used for tiling: Mortar used for tiling must meet the technical requirements in accordance with TCVN 4314:2003 and TCVN 3121:2003 standards. Sand used to make mortar must be sieved. To ensure the requirements for the quality of the solid tiling layer and the working time, it is recommended to use flexible mortar with high adhesion.

2. Construction of cladding

The work of cladding the interior walls of a building with glazed tiles, ceramic tiles, glass tiles, plastic panels, stone panels, etc., is only allowed to be carried out after the load of the building transferred to the wall has reached at least 65% of the design load.

2.1 Cladding with cement sand mortar

When cladding with cement sand mortar, it is necessary to ensure the quality and maintain the fluidity of the mortar throughout the cladding period. The mixed cement mortar must be used within 1 hour.

When cladding with cement sand mortar and the cladding material is fired clay ceramic tiles, if the tiles are dry, they must be dipped or soaked in water before cladding (according to the instructions of the designer or manufacturer).

The sequence of cladding with cement sand mortar is as follows:

- Plaster a layer of mortar with a thickness of less than or equal to 10 mm, smooth it on the cladding surface and wait for the mortar to dry;

- Spread a thin layer of 1:1 cement-sand mortar with a thickness of no more than 3 mm on the back of the tile;

- Attach the tile to the plastered mortar layer, align it in a flat, straight position, press or tap lightly on the tile to create adhesion between the two mortar layers;

- In case the first mortar layer cannot be plastered or when tiling a very small area, it can be directly tiled on the tiled surface by spreading cement-sand mortar on the back of the tile and attaching it to the determined position, aligning and tapping lightly to flatten the tiled surface. The thickness of the mortar layer is about 6mm and not greater than 12mm. This method is not applicable to ceramic tiles with a thickness of less than or equal to 5.5mm because it can easily cause cracking of the tiles.

2.2 Tiling with glue

- The glue used for tiling must be suitable and compatible with the tiled surface; and the tiling material must follow the manufacturer's instructions.

- The surface of the tiled surface must be flat, meeting the specified requirements.

- When tiling with glue, the back surface of the tiling material and the tiling base must be dry; so as not to reduce the adhesive ability of the glue.

- Preparation, mixing of glue and tiling procedures must comply with the regulations of the designer and manufacturer.

2.3 Titling by hook and hanging method

- When tiling materials with large weight and size; such as natural and artificial stone panels, wood panels, ceramics, porcelain, plastic panels, metal; it is necessary to use the hanging and supporting method using hooks; screws, bolts or metal support systems.

- The support and hanger system must be designed; and constructed firmly to attach the tiling material to the load-bearing structural parts of the construction.

- When tiling the exterior of the construction, all details of the support; hangers must be designed or have appropriate treatment measures; to withstand the corrosive effects of weather and environment.

- When tiling large-sized material panels; and large weights require the use of mechanical or semi-mechanized lifting equipment. The scaffolding system for construction must be sturdy; and not affect the operation of the equipment when cladding.

- The construction process of assembling the support system, hangers; and fixing the cladding materials to the structure must comply with the regulations; instructions of the design or the manufacturer.

When tiling the exterior of the building, the upper tiling surface and expansion joints need to be treated appropriately to prevent rainwater from penetrating the back of the tiling surface. To avoid the phenomenon of rainwater stagnation causing stains on the tiling surface; the tiling surfaces of the roof, of the decorative details of the edges; when tiling, the edges should have a slope to drain water.

The last row of tiling at the foot of the wall must not be in contact with the ground; or the tile layer to avoid the phenomenon of water seepage from below; or being affected by the phenomenon of blistering of the ground or the tile layer.

2.4 Tiling joints

- When tiling high, the tiling joints need to be filled with mortar; right during the tiling process within a height of no more than 5m.

- When tiling with cement-sand mortar or tiling with glue through expansion joints; the tiling joints should be arranged to coincide with the expansion joints to prevent cracking and breaking of the tiling material.

- The tiling joints must be straight, even and sharp. The flatness of the tiling joints in the case of flat tiling must not deviate more than 1 mm; when tiling with a joint width of less than 6mm and 2mm; when tiling with a joint width of greater than or equal to 6mm.

- The material used for filling the joints must be selected in accordance with the width and function of the tiling joints.

When tiling each part or the entire surface of the structure, the mortar, putty and stains on the tiling surface must be cleaned. Cleaning the tiling surface should only be carried out after the mortar for the tiling joints has begun to solidify; avoid loosening the tiling joints during the cleaning process.

It is necessary to have protective measures and cover to avoid impact, scratches; or damage to the tiling surface after the tiling work is completed.

3. Inspection and acceptance

3.1 Check

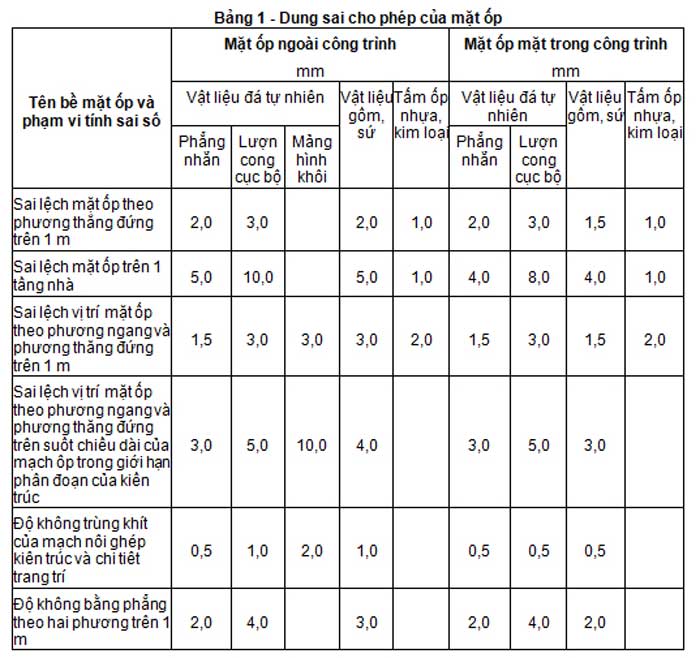

The allowable tolerance of the cladding surface shall not exceed the provisions in Table 1. The quality inspection of the cladding surface shall be carried out in accordance with the construction sequence and shall include the following main criteria:

- Flatness of the cladding surface;

- The solidity and adhesion of the cladding substrate to the cladding material;

- The uniformity of the cladding surface in terms of color, pattern, cladding joints, and decorative details;

- Other special requirements of the design.

The cladding surface must satisfy the following requirements:

- The overall cladding surface must ensure the correct shape and geometric dimensions according to the design requirements;

- The cladding material must be of the correct type, size and color, not warped, chipped, or have defects on the cladding surface; and must not exceed the values specified in relevant technical standards; or design regulations;

- The cladding details and patterns on the cladding surface must be in accordance with the design. The color of the cladding surface made of artificial materials must be uniform;

- The horizontal and vertical tiling joints must be sharp, straight and full of mortar;

- The plaster on the structure must be solid. When checking, there should be no popping sound when tapping on the tiling surface. The tiles that are popping or loose must be removed and re-tiled;

- There must be no cracks or stains on the tiling surface caused by mortar, paint, lime or chemicals;

- When checking with a 2 m long ruler placed close to the tiling surface; the gap between the ruler and the tiling surface must not exceed 2 mm;

- The allowable error for the tiling surface must not exceed the value specified in Table 1.

3.2 Acceptance

Acceptance of the cladding work is carried out at the site. The acceptance documents include:

- Certificate of origin and material testing results;

- Acceptance report of cladding materials;

- Design documents on size, shape and cladding location;

- Completion drawings of the cladding work;

- Acceptance reports of completed work;

- Construction diary.

4. Introducing a reputable design & construction consulting service provider

The importance of construction units is undeniable, their reputation will ensure the quality and aesthetics of your project. Currently, there are many units providing design and construction services to meet the increasing construction needs in our country. Therefore, finding a reputable unit is not easy and requires you to spend time researching. In the selection process, you need to research carefully and ensure that the accompanying unit must have high expertise, many years of experience, have a clearly signed contract, transparent costs, ... To help customers save time searching, Hung Nghiep Phu Construction Investment Co., Ltd. is confident that it will be the best choice for you.

Hung Nghiep Phu Construction Investment Co., Ltd. with the mission of providing the best solutions and services, building a prosperous community with customers, Hung Nghiep Phu is gradually affirming its brand through sincere cooperation, with a leadership team with ethical capacity, creativity, high expertise and strategic vision. Hung Nghiep Phu owns a team of skilled, highly qualified employees who will bring customers the best quality technology.

Hung Nghiep Phu Construction Investment Co., Ltd. with the mission of providing the best solutions and services, building a prosperous community with customers, Hung Nghiep Phu is gradually affirming its brand through sincere cooperation, with a leadership team with ethical capacity, creativity, high expertise and strategic vision. Hung Nghiep Phu owns a team of skilled, highly qualified employees who will bring customers the best quality technology.

Hung Nghiep Phu Construction Investment Co., Ltd. - specializes in constructing civil and industrial works. We look forward to accompanying customers in construction projects as well as continuous procedures such as planning diagrams, applying for construction permits, completing procedures, applying for fire prevention and fighting certificates, ... If you have any questions or are in need of design, completing procedures, please contact us immediately for free consultation!

>>> See more:

_____________________

CONTACT INFO:

![]() Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

![]() Hotline: 1800.3368 (Free)

Hotline: 1800.3368 (Free)

![]() Website: xaydunghunnghiepphu.com

Website: xaydunghunnghiepphu.com

![]() Gmail: kinhdoanh01@xaydunghungnghiepphu.com

Gmail: kinhdoanh01@xaydunghungnghiepphu.com

![]() Address: No. 2034D, Group 22, Phuoc Thai Quarter, Thai Hoa Ward, Tan Uyen City, Binh Duong Province

Address: No. 2034D, Group 22, Phuoc Thai Quarter, Thai Hoa Ward, Tan Uyen City, Binh Duong Province

------

Source: Compiled from the Internet